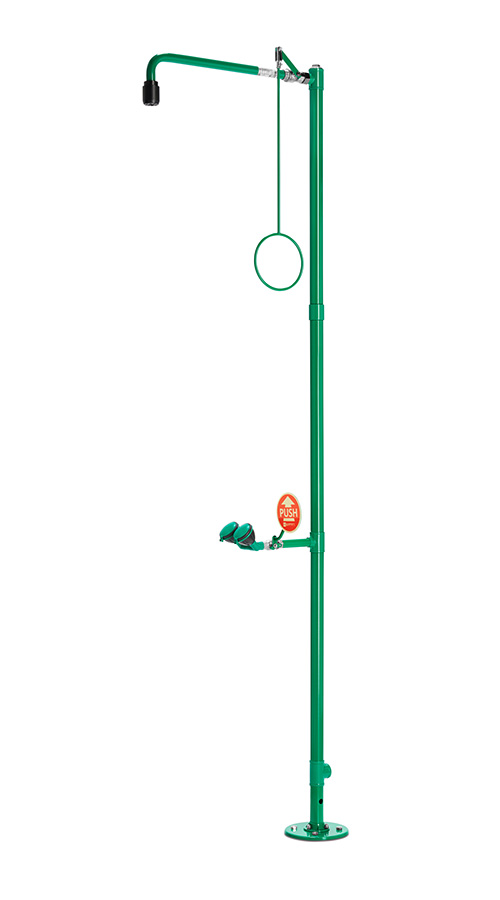

ClassicLine body safety shower with eye shower

The freestanding industrial safety showers are always used when wall mounting of the shower is not possible or when a central point of contact for first aid is to be created. It also makes sense to use them in large halls and production facilities. A big advantage is the good visibility of the shower from all sides. The freestanding safety showers can be optionally adapted to the requirements on site with a wide range of options.

Technical Specifications

- Material: stainless steel, plastic

- Color: green, black

- Total height: 2300 mm

- Projection: 630 mm

- Operating pressure: 1.5 to 3 bar

- Flow rate: 50 l/min (75/110 l/min)

- Water inlet: 1 ¼” female

Norms / Approvals

- EN 15154-2:2006

- EN 15154-2:2006

- EN 15154-5:2019

- ANSI Z358.1-2014

- DIN-DVGW, DVGW, NW-0416CL0425

- DIN-DVGW, DVGW, NW-0417CL0263

- GOST-R, Certificate-No. 0615463 0615463

Product description

The B-SAFETY body safety showers of the ClassicLine series are made of high-quality materials and are just as suitable for use in laboratories and research as they are for rough use in industry. B-SAFETY’s green chemical-resistant polyester powder coating has proven itself in many aggressive environments and is resistant to many acids and alkalis.

The body safety showers are equipped with the B-SAFETY high-performance shower head, which not only meets the specifications of ANSI Z358.1 and EN 15154, but is also self-draining, largely free of calcificationand maintenance, and very robust and corrosion-resistant. The limited, uniform and above all soft water jet is optimized for rinsing off chemicals on the skin.

Technical Description

- including top and bottom water inlet 1 ¼” female for installation in circulation lines, plug 1 ¼” of stainless steel

- base plate with 4 mounting holes of stainless steel, chemical resistant green powder coated, diameter 200 mm

- stand pipe 1 ¼” of stainless steel three-part, chemical resistant green powder coated, with top and bottom water inlet 1 ¼” female, total height 2300 mm

- connection piece of stainless steel, for easy installation and alignment of the shower

- ball valve ¾” made of dezincification-resistant brass, with quick connect system and pull rod actuation, DIN-DVGW tested and certificated

- pull rod with ring handle of stainless steel, chemical resistant green powder coated, length 700 mm

- wall shower arm ¾“ of stainless steel, chemical resistant green powder coated, projection 630 mm

- integrated automatic flow regulation 50 l/min. for a spray pattern acc. to the norms at a specified operating range of 1.5 to 3 bar dynamic water pressure

- high-performance shower head of chemical resistant plastics, black, with improved spray pattern, corrosion resistant, largely calcification- and maintenance-free, very robust, self-draining

- sign for body safety shower according to EN ISO 7010 und ASR A1.3, self-adhesive PVC-film, 150 x 150 mm, viewing distance 15 metre

- integrated ClassicLine safety eye shower with two spray heads 45°, mounting height 970 mm, orientation of eye shower freely selectable on site

- connection pipe of stainless steel for easy installation and alignment of the shower, chemical resistant green powder coated, water inlet ¾” male

- ball valve ½” of stainless steel, with PUSH-lever actuation, DIN-DVGW tested and certificated

- big push plate made of steel, chemical resistant green powder coated, length 130 mm, with large signal “PUSH”, luminescent according to DIN 67510

- integrated flow regulation 14 litre / minute for a standard-compliant jet pattern at a specified working range of 1.5 to 5 bar flow pressure

- high-performance spray heads for large-scale dispersion of water, 45° angled, with plastic spray plate, largely free of calcification, with rubber sleeves and sealed dust caps with folding mechanism, mounted over distributor fork

- sign for eye shower according to EN ISO 7010 und ASR A1.3, self-adhesive PVC-film, 100 x 100 mm, viewing distance 10 metre

- according to BGI/GUV-I 850-0, DIN 1988 and EN 1717

- according to ANSI Z358.1-2014, EN 15154-1:2006, EN 15154-2:2006 and EN 15154-5:2019

- DIN-DVGW tested and certificated

Do you have questions or would you like advice?

You can reach us Monday to Thursday from 8 am to 5 pm and Friday from 8 am to 2 pm.

WE LOOK FORWARD TO YOUR MESSAGE

CONTACT

Do you have questions or need help? Send us an email and we’ll get in touch shortly.